Materi […]

Material preparation

Round nails, electrodes, solder, dilute hydrochloric acid, cement, etc.

Main equipment

Electric welding machine, electric iron, wooden hammer, steel ladles, steel needles, square steel, screwdrivers, scribe gauges.

Operating conditions

1. The roof leveling construction has been completed and passed the inspection and acceptance.

2. The roof must be provided with a protective fence for construction and installation to ensure the safety of operation such as installation of water drops.

Operation process

1. Process flow:

Installation of antirust layer— → finding and positioning— → installation— → fixing— → painting.

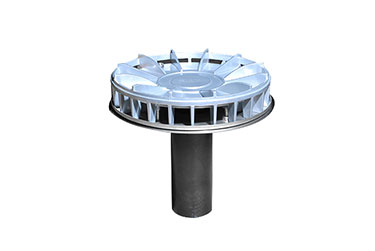

Rain bucket installation

1) Find the installation location:

According to the design location and requirements, during the construction of the structure, water outlet holes are reserved. The rainwater bucket of the water outlet should pop up rainwater before installation.

The centerline of the bucket is to find a good elevation. The rain bucket is stabilized with cement mortar, embedded with fine stone concrete, and tightly packed.

2) Brush painting: After the rainwater bucket is installed [3], the surface paint of the rainwater pipe exposed surface is brushed to the design requirements.

Quality Standard

1. The variety and specifications of the rain bucket must meet the requirements and have a factory certificate.

2. The installation of the rainwater bucket and the deformation joint must be firm. The firm method and spacing should meet the requirements of the specification. The drainage should be smooth and not leak.

3. The elevation of the rainwater bucket must be the same, and the surface inside and outside the rainwater bucket wall must be in a straight line.