HDPE drainage pipe fittings

For same floor, siphon drainage system

Note: The product size is for reference only, the actual size is subject to the actual product.

Flange connection is to fix two pipes, fittings or equipment on a flange respectively, then add a flange pad between the two flanges, and finally tighten the two flanges with bolts. It is a detachable joint which is tightly combined.

The flange connection process is as follows:

The connection of flanges and pipes must meet the following requirements:

1. The center of the pipe and flange should be on the same horizontal line.

2, the center of the pipeline and the sealing surface of the flange into a 90-degree vertical shape.

3. The position of flange bolts on the pipeline should be consistent.

Second, gasket flange gasket requirements are as follows:

1. In the same pipeline, the flanges of the same pressure should be selected with the same gasket, so that they can be exchanged later.

2. For pipes using rubber plates, it is best to choose rubber gaskets, such as water pipes.

3. The selection principle of the gasket is: choose as close to the small width as possible. This is the principle that should be followed on the premise that the gasket will not be crushed.

Third, the connection flange

1. Check whether the specifications of flanges, bolts and gaskets meet the requirements.

2. Keep the sealing surface smooth and tidy without burrs.

3. The thread of the bolt must be complete without defects, and the fitting must be natural.

4. The texture of the gasket should be flexible, not easy to age, and the surface should not be damaged, wrinkles, scratches and other defects.

5. Before assembling the flange, the flange should be cleaned, oil, dirt, rust and other debris should be removed, and the sealing line should be removed.

Fourth, the mounting flange

1. The flange sealing surface is perpendicular to the center of the pipeline.

2. Bolts of the same specifications have the same installation direction.

3. The flange installation position on the branch pipe should be more than 100 mm from the outer wall surface of the riser and 200 mm or more from the wall surface of the building.

4. Do not bury the flange directly in the ground, it is easy to be corroded. If it must be buried in the ground, it is necessary to do anticorrosive treatment.

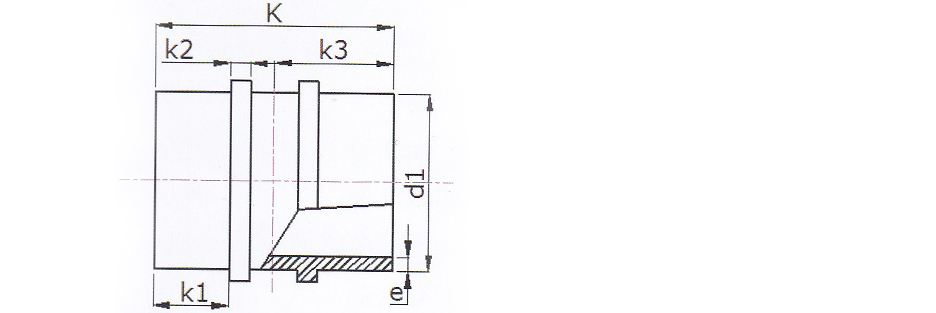

| Article No | d1 / d2 | K | k1 | k2 | k3 |

| 10.18.200 | 200 | 210.7 | 68 | 16 | 105.4 |

| 10.18.250 | 250 | 225.4 | 71 | 20.7 | 112.7 |